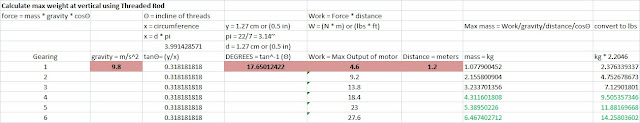

Here is the math for using pulleys on a vertical plane. Using the formula Force = mass * gravity and Work = Force * distance. I

substituted Force into the work equation. Input the knowns, distance = 1.2 m, max work capable per the specs of the motor = 4.6 Nm, and

gravity = 9.8 m/s^2. Re-wrote the equation to solve for mass (kg).

I then calculated for adding additional wheels to multiple the force of the motor. Each multiplier equals each line connected to the mass which in the illustration has 6 total top and bottom.

That still was not enough force multiplier. I then calculated gearing and settled on 1:3 which means that for each rotation of the motor, the mass will move a little over 5/16 of an inch.